When we combine the terms Cognition Y Ergonomics We do this to indicate that our objective is to study the cognitive aspects of interaction between people, the work system and artifacts that we find in it, in order to design them so that the interaction is effective. Cognitive processes such as perception, learning or problem solving play an important role in the interaction and must be considered to explain cognitive tasks, such as the search for information and its interpretation, decision-making and the solution of problems, etc. In Online Psychology we are going to offer you a definition of cognitive ergonomics with examples so that you can understand well what we mean when we talk about this term.

Index

- What is cognitive ergonomics

- Human errors

- Human errors in cognitive ergonomics

- Interface Design

- Process control systems

- The phenomenon of complacency

- Conclution

What is cognitive ergonomics.

The Ergonomicsis defined as the

The ergonomist's goal is to describe the relationship between the human being and all the elements of the work system. It should be noted that in the relationship between the person and the work system we can highlight two relatively different aspects:

Physical ergonomics

On the one hand, we have the purely physical aspect that refers to the muscular and skeletal structure of the person. For example, a person working in an office may be sitting (typing on a computer) or standing (making photocopies). The position you have in the two situations is different and the design of the job has to be done thinking about the characteristics of the structure of the human body so that the person is comfortable, does not get tired, does not develop any pathology of the spine, etc.

Physical Ergonomics deals with this aspect and is perhaps the most popular. For example, when a new 'ergonomically designed' car is advertised, the tagline often means that, for example, the height of the steering wheel is adjustable to suit the height of the driver.

Psychological or cognitive ergonomics

However, there is another aspect of the relationship between the person and the work system that refers to how a person knows and acts. In order to carry out their task, a person has to perceive the stimuli in the environment, receive information from other people, decide what actions are appropriate, carry out these actions, transmit information to other people so they can carry out their tasks, etc.

All these aspects are the object of study of Psychological or Cognitive Ergonomics (Cañas and Waern, 2001). In the design of a car, we will be interested in how the information is presented to the driver. For example, when designing the speedometer we can do it using analog or digital indicators. Each indicator has its advantages and disadvantages in terms of how the driver perceives and processes speed information.

Although the two aspects, the physical and the psychological, are not totally independent, in Cognitive Ergonomics we are interested in the second and we refer to the first to the extent that it has psychological consequences. For example, if an air traffic controller adopts a certain uncomfortable posture, his fatigue will increase and this will have psychological effects such as decreasing his level of alertness.

Human errors.

An area of application of Cognitive Ergonomics that has a long tradition and that is currently receiving a great deal of attention is that of prediction and avoidance of so-called "Human Errors or Failures".

Many times we are surprised by the news of a tragic accident such as when a train derails causing the death of a large number of people. These accidents occur when a machine (ex. a train), which is being controlled by a person (ex. the machinist), has inappropriate behavior (eg. derails). Therefore, in the first steps of the investigation, the technicians focus their attention on the possible existence of a technical fault. However, it is often the case that after a careful examination of the machine, no malfunction of its components is found. They then shift their attention to the other possible culprit for the accident, the person who was controlling the machine.

Unfortunately, the first thing that jumps to the front pages of the press is the suspicion that this person had altered his physical or mental conditions. Therefore, doctors, under the orders of an investigating judge, begin to carry out analyzes, looking for traces of alcohol, drugs or any other substance that justify abnormal behavior. However, the bewilderment of the technicians and the public is evident when these analyzes do not reveal anything either. The person who controlled the machine was in perfect physical and mental condition. What happened then?

Often at this point we hear that "the accident was due to human error." That is, the person who controlled the machine, in perfect health, has made an incomprehensible mistake. Obviously, the possibility that the error was intentional is ruled out. Nobody wants to crash a train. Therefore, the question that remains in the air is why did he make the mistake? It is not enough to label the accident as due to human error or failure.

Human errors in cognitive ergonomics.

In Cognitive Ergonomics we take as a starting point the definition of human error that has been proposed by Reason (1992) who considers it as' a generic term used to designate all those occasions in which a planned sequence of mental or physical activities fails to achieve its intended result, and when these failures cannot be attributed to the intervention of some factor of chance'.

In similar terms Sanders and McCormick (1993) define human error as' a human decision or behavior inappropriate or undesirable that reduces, or has the potential to reduce, the effectiveness, safety, or performance of the system'.

In any case, human error is a failure to perform a task satisfactorily and cannot be attributed to factors that are beyond the immediate control of the human being. To understand why a person makes a mistake, we must begin by considering that controlling a machine means establishing communication between it and the person. From this point of view, the machine must have means of transmitting to the person your internal state.

The importance of machine design

Thus, when the engineer builds it, he designs panels with all kinds of indicators (dials, screens, etc.) designed to offer all the information that the operator is considered to need to control it correctly. Furthermore, since this communication occurs within a physical environment on which the machine operates, Signs are also designed that present information about the external conditions in which they are works.

Finally, the communication between person and machine it almost always occurs in situations where other people and other machines are involved. Communication between all of them is established through technical means designed so that the information is received and processed correctly by the person who needs it.

For all this, for many years it has been recognized that the cause of these human errors often has to be look for it in a possible bad design of the machine, of the informational signs or of the means of communication between the people.

Interface Design.

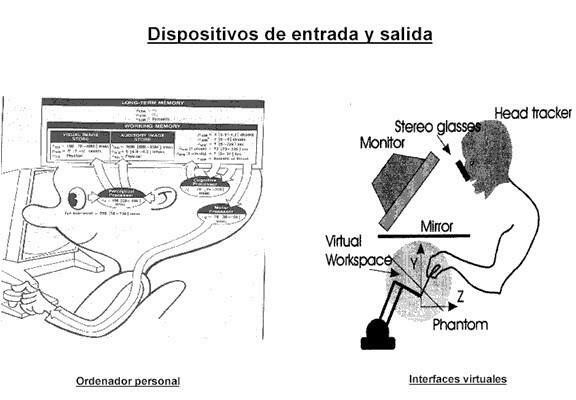

Thus considered the design, the most important component of the machine for a cognitive ergonomist is the interface with which the operator interacts. In a simple way, we can say that an interface is the "medium" through which the person and the machine communicate. This communication is established in both directions. Therefore, when speaking of an interface we must include the means by which the machine presents information to the person and the means by which the person enters information into the machine.

The number of input and output devices that are available in today's interfaces is so large that it is not possible to classify them in an easy way. However, since computer technology has been introduced in almost all machines that are currently designed, interface design is studied fundamentally within an area of modern Cognitive Ergonomics called ‘Interaction Person-Computer '.

The progress we are seeing in interface design today is so rapid that it is forcing cognitive ergonomists to investigate interaction in contexts new to humans. For example, we are moving from interacting with personal computers that have a screen, keyboard and mouse, to virtual interfaces where the input and output devices will allow interaction experiences that can exceed the natural capacities of beings humans.

With the personal computer the interaction occurs through senses of sight and hearing fundamentally. However, in virtual reality environments, humans can interact with machines, for example, through the vestibular sense that informs the brain about the balance of the body human.

Thus, Cognitive Ergonomics is currently facing challenges new to apply the research of Psychology and Neurosciences to the design of interfaces so that they are adapted to the conditions in which human work takes place.

Process control systems.

The design of industrial process control systems is an area where cognitive ergonomists work regularly and can help us to illustrate the importance of interface design in the context of the prevention and avoidance of human errors.

Process chains occur in the energy transformation and chemical manufacturing industry that have to be controlled by human beings through artifacts that serve to present information and act on the operations that are taking place inside and outside the industrial complex. The interaction of the people in charge of this control with the artifacts generally occurs within the so-called operations control rooms. In these control rooms we can find a good example of the importance that a good interface design has from the point of view of the prediction and avoidance of human errors.

The task of a person in a process control room is to supervise what happens, intervene when required, know the status of the system, reprogram it, take control of automated processes when necessary and plan future actions in the short and long term (Sheridan, 1997). All these functions refer to human cognitive processes whose correct operation depends on a good design of the human-machine interaction.

To make supervision possible interfaces need to present information on the state of the system in such a way that it can be attended, perceived, understood, memorized, etc. For example, we know from psychological research on eye movements that they do not occur at a speed of more than two per second. Therefore, it is not advisable to present information at a rate that exceeds this speed (Vicente, 1999).

The phenomenon of complacency.

However, when an accident occurs, it is the human being who has to take control over the process by interacting with the artifacts directly. Even under normal conditions it is recommended that operations do not leave everything in the hands of the automatic systems. because it has been shown that then we can encounter a phenomenon known as complacency (Parasuraman and Riley, 1997). This phenomenon occurs when the person is overly confident in the proper functioning of the automatic system and it stops supervising (interacting) the process, in such a way that when the problem appears it does not detect the need to intervene.

For this reason, the design of control rooms has undergone a change in philosophy in recent years that is in line with recognize the importance of human-machine interaction and, therefore, of the contribution of Cognitive Ergonomics in this context.

In the classical conception, the control rooms were designed thinking that the machines should be automatic and the person should only act when the accident occurred. However, it is now thought that the design of these rooms should be done from the conception based on the strategy that Zwaga and Hoonhout (1994) called supervision through conscious awareness of the situation.

Perception of the elements in the environment

Whenever a person is in a situation, anyone has a knowledge of what is happening in his environment. Even when we are sitting around doing nothing, we have information about everything that happens around us. However, when we have to perform a complex task such as that carried out in a control room, we need to process a huge set of data about what is happening inside and outside her. All this information must be attended, retained, interpreted and used to make the necessary decisions so that the industrial process progresses correctly.

All this is called acquiring, processing and using Situation Knowledge, which has been defined as “the perception of the elements in the environment within a volume of time and space, the compression of its meaning and the projection of its state in the near future ”(Endsley, 1995).

In many of the application domains of Cognitive Ergonomics, such as air traffic control, piloting aircraft, or the control of a nuclear or thermal power plant, ergonomists have needed to use this concept in order to describe and integrate all cognitive processes that they are responsible for the acquisition, storage and use of the information that is available so that the person can carry out the work in them and, in this way to help the design of the work system to be appropriate for the human being, improving their well-being and avoiding the fearsome mistakes humans.

Conclution.

The importance that Ergonomics is currently acquiring as a scientific discipline that can contribute to improve human well-being it requires that we make an effort to define its object of study well. In this sense, in this work we have wanted to draw attention to the two aspects, the physical and the psychological, which are important to differentiate in the relationship of the human being and the system where he works and that give rise to distinguish two sub-disciplines within Ergonomics: Physics and Cognitive.

This article is merely informative, in Psychology-Online we do not have the power to make a diagnosis or recommend a treatment. We invite you to go to a psychologist to treat your particular case.

If you want to read more articles similar to Cognitive ergonomics: definition and examples, we recommend that you enter our category of Cognitive psychology.

References

This article was originally published in Senior Management: Cañas, J.J. (2003). Cognitive ergonomics. Senior management, vol. 227, 66-70

Bibliography

- Cañas, J.J., and Waern, Y. (2001). Cognitive ergonomics. Madrid: Editorial Médica Panamericana.

- Endsley, M. (1995a). Toward a Theory of Situation Awareneness in Dynamic Systems. Human Factor, 37 (1), 32-64.

- Miller, G.A. (1956). The magical number seven plus or minus two: Some limits on our capacity for processing information. Psychological Review, 63, 81-97.

- Parasuraman, R. and Riley, V. (1997). Humans and automation: Use, misuse, disuse, abuse. Human Factors, 39, 230-253.

- Reason, J. (1992). Human Error. New York: Cambridge University Press.

- Sanders, M.S., and McCormick, E.J. (1993). Human Factors in Engineering and Design. McGraw-Hill, Inc.

- Sheridan, T.B. (1997). Supervisory control. In G. Salvendy (ed.) Handbook of Human Factors. New York: Wiley.

- Vicente, K.J. (1999). Cognitive work analysis: Toward Safe, Productive and Healthy Computer-based Work. Marwah: READ.

- Zwaga, H.J.G., and Hoonhout, H.C.M. (1994). Supervisory control behavior and the implementation of alarms in process control. In N.A. Stanton (ed.) Human Factors in Alarms Design: London: Taylor and Francis.