The beginning of the supply chain industry operations researchAs well as industrial engineering, they started with logistics. Both industrial engineering and operations research have their roots in logistics.

Fredrick Taylor, who was the author in 1911 of the book The Scientist's Principles and is considered to this day as the father of industrial engineering, he was in charge of doing the first research on how to improve the manual process of a load.

Advertisements

This research began when scientists revealed the great value of studying the problems of military logistics in 1940. It was all due to the consequences of World War II. While industrial engineering and operations research have attempted to maintain separate identities, many of their greatest successes have occurred when used in an integrated framework to address logistics and supply chain issues. supply. Increasingly, the industry refers to this as'Supply Chain Engineering«.

One concern, at the most fundamental level, is that unless we can describe what we do and demonstrate our success to our stakeholders, we cannot earn their recognition and support.

Advertisements

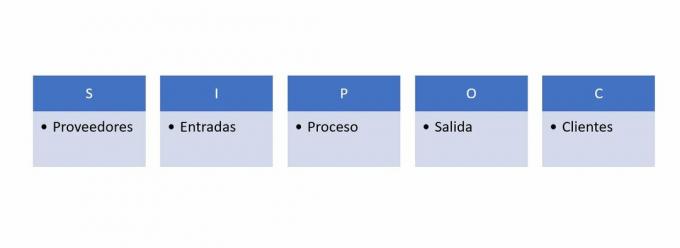

By defining the «supply chain»As the functions and activities involved in the production of goods or services From the supply of components / raw materials to the finished products that are provided to the consumer, this begins to build an image.

Advertisements

In this article you will find:

Stages

In its simplest form, the stages of a supply chain are those described within the Value chain of Porter and this can be considered a good guide for the structure of the supply chain.

- Logistics

- Operations

- Marketing and sales

- Services

Benefits and importance

The objective of supply chain management is comprehensively analyze the entire supply chain from supplier to consumer, and review three core areas of people, processes and systems to maximize the value of all activities.

Advertisements

Among the benefits of implementing supply chain management are:

- Quality control improves.

- There is a better collaboration.

- The rate of efficiency increases.

- The company keeps up with the demand.

- Overhead costs are reduced.

- Shipments are optimized.

- Cash flow improves.

- Risk mitigation improves.

Supply chain examples

Tesla

The first of the supply chain examples is Tesla. Automotive manufacturing has come a long way since Henry Ford used assembly line manufacturing to accelerate the production of a single model car in a single color.

Advertisements

Now, at a time when even American automakers are opening factories abroad, Tesla is making innovative, incredibly popular and luxurious cars in California, a location with incredibly real estate expensive.

Instead of having a long supply chain of cheap parts manufacturers, have a vertically integrated supply chain, with a full-service auto plant near its corporate headquarters and plans for a supplier park and a huge battery factory, and Tesla owns it all.

Even more interesting is the digital supply chain that the company promotes: new ones are shipped firmware and algorithm updates to existing car owners through the cloud.

Amazon

Having surpassed the supermarket chain Walmart as the world's largest retailer in the last decade, Amazon's “big box online” concept is one of the perfect supply chain examples unique.

As an ecommerce store, they obviously cut out the retail store and ship directly from the distribution center to consumers' homes. Amazon innova is both on the supplier side and on the final link in the supply chain: delivery.

Almost anyone can sell things on Amazon because it is a platform, not just a store. As a result, Amazon has more stuff than any other online store, so when people shop online, they think of Amazon.

Then it produces low-priced everyday goods and offers fewer offers to suppliers. Next, your warehouses make serious use of automation to store items going to similar destinations together, ready for immediate transport.

McDonald’s

The leading fast food brand has consistently positioned itself prominently for its excellent supply chain management due to a system in which success is shared and value is exchanged between McDonald’s and its suppliers.

This approach has met with great success, as McDonald’s is now in more than 100 countries with more than 35,000 restaurants serving 68 million people every day.

PepsiCo

As one of the world's leading food and beverage companies, PepsiCo is the parent company of hundreds of diverse and beloved domestic brands. The company has done a great job transitioning its supply chain capacity to handle more complex products and follow consumer trends toward foods more nutritious than carbonated soft drinks and processed snacks.

PepsiCo has developed significant enhancements such as sustainability initiatives, collaborative production scheduling, establishment of inventory reserves and selective procurement and sourcing, for a resilient supply chain and efficient.

Unilever

British-Dutch consumer goods company Unilever is the third largest of its kind, offering food, beverages, personal care products and cleaning agents. In early 2000, Unilever embarked on a five-year growth strategy, which included a significant restructuring of its supply chain management.

Other of the supply chain examples are the following companies:

- Coke

- Cisco

- Nestle

- 3M

- Jonhson & Jonhson

- Nike, among others.