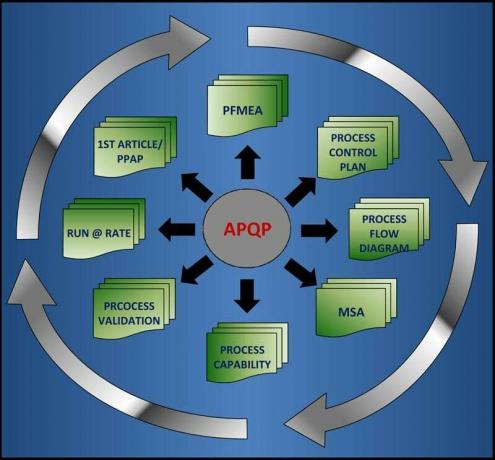

APQP It is a defined process for product development in various industries, especially automotive. It encompasses a series of procedures and techniques, the objective of which is to develop a quality plan that benefits product development and satisfies customer needs. Like the PPAP, SPC, MSA and FMEA, the APQP is considered a core tool of the automotive sector.

In this article you will find:

What is APQP?

Advertisements

The APQP (Advanced Product Quality Planning) was born in 1980, through the commission formed by the companies Ford, Chrysler and GM. Since then they have used this tool, including its suppliers and certain affiliates.

It is used as a development guide and a means of connection between automotive companies and their suppliers, being an efficient way to share their results.

Advertisements

Phases of APQP

APQP focuses on

It is necessary to analyze these processes in detail for the results to be positive.

Advertisements

1. Define the Program

Potential clients are studied to define what their expectations are, in order to carry out the design and functionality of the final product. Tools such as lists are used, specifying the ideal aspects that the product should have, as well as a diagram that graphs the flow of the production process.

Thanks to this, the product can be elaborated, with each of its characteristics necessary for manufacturing, guaranteeing the final quality. Each department plays an essential role, despite its different characteristics and responsibilities.

Advertisements

2. Design and Create the Product

The team in charge of monitoring and reacting to any problem meets. Businesses often call it "design and analysis failure mode," and it consists of specifying the different guidelines and engineering. It is crucial to verify every detail in the development of the first prototype, to be able to adjust the defects in time, before starting mass production.

The planning team is tasked with monitoring the quality of the team. It requires establishing the basic requirements, defining the key points of the product and production, with the support of the administrative sector.

Advertisements

3. Align Manufacturing Processes

The team focuses its attention on the elements that are part of the production process, since its objective is to guarantee good results, while maintaining efficiency and productivity. Failures in design and methods must be avoided. Many companies call this process "failure mode effects."

Based on the system analysis, the team will adjust the plan if necessary. In turn, they will be responsible for the development of a plan that will be in charge of the specifications and details of the packaging.

4. Product Validation

The fourth phase consists of the production test. Its purpose is to see if the process has been carried out correctly, if the results are positive or if there is a failure in any of the steps. This test is of vital importance, measurement tools are used to carry out a precise study of the components and the product itself.

5. Evaluation And Correction

Of course, plans can vary and none are considered perfect. For this reason, the last phase consists of the adjustments that must be made to improve the product. The studies carried out will help to make the right decision, whether to correct or improve the result.

The quality will depend on the capacity and the objective previously set. Corrective action can be of the entire global process, or only of some steps. Whatever it takes for the product change to meet the customer's need.

APQP Examples

Large companies worldwide use this type of plan. Today the first companies that used it still maintain the quality of their services, and consequently, the trust and recognition of their customers. These are Ford, General Motors, and Chrysler.

Many companies make use of this type of plan because it allows them to develop products following the market trend, despite the drastic changes observed internationally.

Some of the most important examples are companies belonging to the technological field, such as Apple, because they require tactics that allow them to adapt to the specifications of their customers. For this reason it is common to see that companies design and launch products in short periods of time.