Industrial Maintenance

Industrial maintenance can be defined as a set of standards and techniques established for the conservation of the machinery and facilities of an industrial plant, so that it provides better performance in the longest time possible.

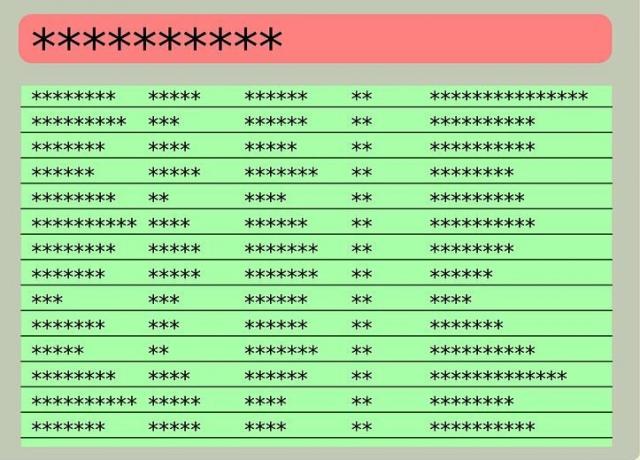

Advertisements

Types of Industrial Maintenance

1.1. Corrective

Advertisements

It includes the maintenance that is carried out in order to correct the defects that a piece of equipment or machinery has presented. It is classified in:

Unplanned. It's emergency maintenance. It must be carried out urgently either due to an unforeseen breakdown to be repaired as soon as possible or due to a condition imperative that must be satisfied (problems of safety, contamination, application of legal regulations, etc.).

Advertisements

Planned. What needs to be done is known in advance, so when the team is stopped to perform the repair the personnel, spare parts and technical documents necessary to carry it out are available correctly

1.2. Predictive

Advertisements

This maintenance is based on the inspection to determine the status and operability of the equipment, through the knowledge of variable values that help to discover the state of operability; This is done at regular intervals to prevent failures or avoid their consequences.

For this maintenance it is necessary to identify the physical variables (temperature, pressure, vibration, etc.). These variations are an indication of when equipment damage may be caused. It is the most technical and advanced maintenance that requires analytical and technical knowledge and requires sophisticated equipment.

Advertisements

1.3. Preventive

It is the maintenance that is carried out in order to prevent the occurrence of failures, and maintain the equipment, is known as direct or periodic preventive maintenance, since its activities are controlled by the weather; it is based on the reliability of the equipment.

This type of maintenance has methodologies and procedures that can be applied to other areas. For example, in project management it is always better to predict a mistake, to be prepared for it rather than to spend more money on contingencies in the future.